Performance Grade (PG) Bitumen

Due to the inadequacy of penetration and viscosity based grading systems, the Strategic Highway Research Program (SHRP) in the US conducted a Project between 1987 and 1993 in order to overcome the shortcomings of empirical systems. One consequence of this Project was a performance-based binder specification with a new set of tests. The final product of the SHRP bitumen research program is a new system referred to as SUPER-PAVE, which stands for Superior Performing Asphalt Pavements and called as binder specification because it is intended to function equally well for modified and unmodified bitumen. Performance Grade (PG) Bitumen is bitumen which is graded based on its performance at different temperatures. In Super-pave grading system, binders are classified according to their performance in extreme hot and cold temperatures and called as performance grade (PG) bitumen. The main purpose of grading and selecting asphalt binder using the PG system is to make certain that the binder has the appropriate properties for environmental conditions in the field. PG asphalt binders are selected to meet expected climatic conditions as well as traffic speed and volume adjustments.

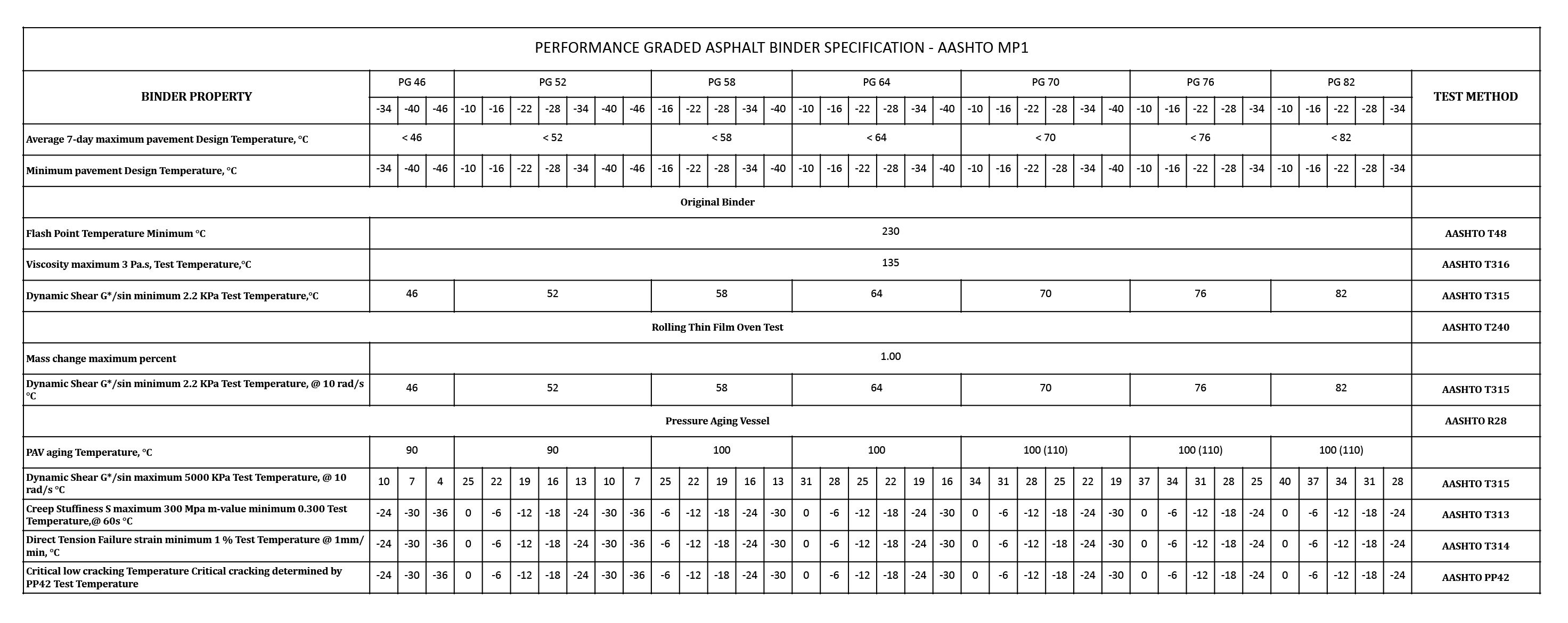

Therefore, the PG system uses a common set of tests to measure physical properties of the binder that can be directly related to field performance of the pavement at its service temperatures by engineering principles. It is one of the most important changes introduced in Super pave that acceptance limits are the same but have to be met at specific pavement temperature and traffic conditions.

The Long-Term Pavement Performance (LTPP) has given a certain algorithm to calculate the temperature of the pavement based on the temperature of the air above. From this, the highest and the lowest temperatures of the pavement are calculated and the bitumen that performs well in that temperature range is selected. Penetration grading and viscosity grading are somewhat limited in their ability to fully characterize asphalt binder for use in Hot Mix Asphalt (HMA) pavement. Therefore, as part of the Super-pave research effort, new binder tests and specifications were developed to more accurately and fully characterize asphalt binders for use in HMA pavements. These tests and specifications are specifically designed to address HMA pavement performance parameters such as rutting, fatigue cracking, and thermal cracking. Super-pave performance Grade (PG) Bitumen is based on the idea that an HMA asphalt binder’s properties should be related to the conditions under which it is used. For asphalt binders, this involves expected climatic conditions as well as aging considerations. Therefore, the PG system uses a common battery of tests (as the older penetration and viscosity grading systems do) but specifies that a particular asphalt binder must pass these tests at specific temperatures that are dependent upon the specific climatic conditions in the area of use. This concept is not new – selection of penetration or viscosity graded asphalt binders follows the same logic – but the relationships between asphalt binder properties and conditions of use are more complete and more precise with the Super-pave PG system. Information on how to select a PG asphalt binder for a specific condition is contained in Super-pave mix design method.

Performance Grade (PG) Bitumen Nomenclature

Performance Grade (PG) bitumen cement based on two factors: traffic and pavement temperature. Adjustments are made to the PG grade of asphalt cement based on traffic conditions and traffic volumes which are intended to enhance the design life of the pavement. The PG grading system is defined by two numbers, which represent pavement temperatures. The first number PG 64-XX represents the high pavement temperature in degrees Celsius, while the second number PG XX-22 represents the low pavement temperature. Notice that these numbers are pavement temperatures and not air temperatures (these pavement temperatures are estimated from air temperatures using an algorithm contained in the LTPP Bind program). All adjustments to the PG grading system are made in six (6) degree increments. The high temperature relates to the effects of rutting and the low temperature relates to cold temperature and fatigue cracking.

PG PERFORMANCE GRADE BITUMEN