Bitumen Standards & Grades

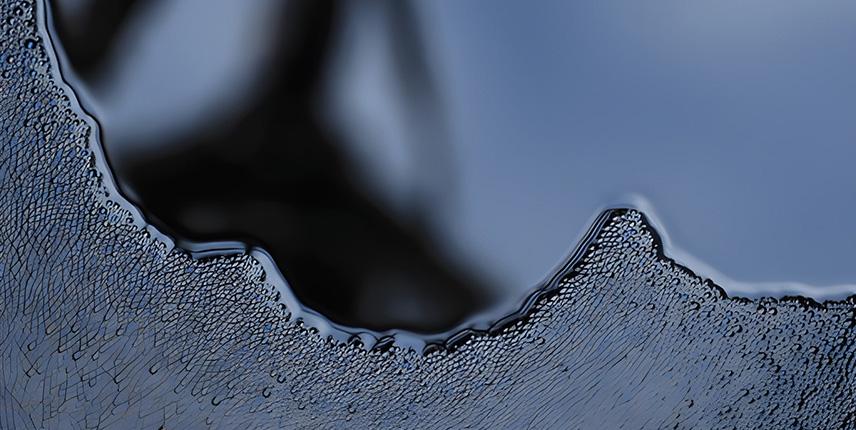

Bitumen plays a vital role in modern construction, from road paving to waterproofing systems. To ensure consistency and performance, bitumen is classified into different standards and grades based on its physical and chemical properties.

These classifications are set by international and regional authorities such as ASTM, EN (European Norms), AASHTO, and various local standards. Understanding these categories helps engineers and builders select the most suitable bitumen for each project, ensuring long-term durability, safety, and efficiency.

Why Bitumen Standards Are Important

Bitumen is used worldwide under diverse environmental conditions, from freezing climates to desert heat. Standardization allows manufacturers, contractors, and government agencies to speak a common technical language.

By defining measurable properties such as viscosity, penetration, and softening point, these standards:

- Guarantee consistent product quality

- Ensure compatibility with local climate and traffic conditions

- Facilitate safe and efficient construction practices

- Support global trade and technical comparisons

International Standards for Bitumen

Several key organizations regulate and define bitumen standards globally. Each focuses on testing methods and classification systems suited to specific regions or industries.

ASTM (American Society for Testing and Materials)

The ASTM standards are widely used in North America and globally.

Common ASTM standards include:

- ASTM D946 – Penetration-graded bitumen

- ASTM D3381 – Viscosity-graded bitumen

- ASTM D6373 – Performance-graded (PG) bitumen

These standards specify how to measure penetration, viscosity, and performance characteristics to ensure the material meets highway and infrastructure requirements.

EN (European Norms)

In Europe, bitumen classification follows EN 12591 for paving grade bitumen.

The EN system focuses on softening point, penetration, and temperature susceptibility, ensuring that bitumen performs well under European climate variations.

Example grades:

- EN 12591 35/50 – Harder bitumen for hot climates or heavy traffic

- EN 12591 50/70 – Standard road paving bitumen

- EN 12591 70/100 – Softer grade suitable for colder climates

AASHTO (American Association of State Highway and Transportation Officials)

The AASHTO M320 standard defines Performance-Graded (PG) bitumen.

Unlike penetration or viscosity grading, PG bitumen is based on expected service temperature ranges, both high and low, to ensure performance under local weather and loading conditions.

For example:

- PG 64-22: Performs well between 64°C (high temperature) and -22°C (low temperature).

- PG 76-10: Enhanced for high-traffic or hot regions.

Local and Regional Standards

Many countries have adopted modified versions of international standards to address local climate and material availability.

For instance:

- IS (India) – Indian Standards such as IS 73 for paving bitumen.

- BS (UK) – British Standards based on penetration values.

- AS (Australia) – Australian Standards that consider extreme temperature variations.

Types and Grades of Bitumen

Bitumen grades are classified based on how they behave under different conditions, such as heat, pressure, or loading. The most common types include:

1. Penetration Grade Bitumen

This is one of the oldest and most widely used classifications. The grade number (e.g., 60/70, 80/100) refers to the depth (in tenths of a millimeter) that a standard needle penetrates the bitumen sample under specific conditions.

- 60/70: Suitable for hot climates and heavy traffic.

- 80/100: Used in moderate or cooler regions.

Penetration grade bitumen is ideal for flexible pavements and general road surfacing.

2. Viscosity Grade Bitumen

Viscosity grading, used mainly in the U.S. and Asia, measures flow resistance at a specific temperature. Common grades include VG-10, VG-20, VG-30, and VG-40.

- VG-10: Best for cold climates.

- VG-30: Common for road construction in warmer areas.

- VG-40: Used in heavy-duty highways and industrial zones.

3. Performance Grade (PG) Bitumen

The Performance Grade (PG) system evaluates bitumen based on actual climate conditions, including the highest and lowest pavement temperatures.

This modern approach ensures the bitumen performs reliably under both hot summers and cold winters, making it ideal for long-lasting asphalt pavements.

4. Cutback and Emulsion Bitumen

In addition to paving grades, cutback and emulsion bitumen are used for surface treatments, sealing, and maintenance.

- Cutback Bitumen: Bitumen mixed with solvents for easy application.

- Bitumen Emulsion: Water-based, eco-friendly alternative for cold weather paving and tack coats.

Choosing the Right Bitumen Grade

Selecting the correct bitumen grade depends on several factors:

- Climatic conditions (temperature range and rainfall)

- Traffic load and intensity

- Pavement type (flexible or rigid)

- Construction technique

Using the right standard and grade ensures better performance, fewer cracks, and extended pavement life.

Conclusion

Bitumen standards and grades form the backbone of quality control in modern infrastructure. Whether defined by ASTM, EN, AASHTO, or national authorities, these systems ensure that every bitumen product performs reliably under specific environmental and structural demands.

By understanding these classifications and selecting the right grade, engineers can design safe, durable, and cost-effective pavements and waterproofing systems that stand the test of time.