Bitumen Production Process

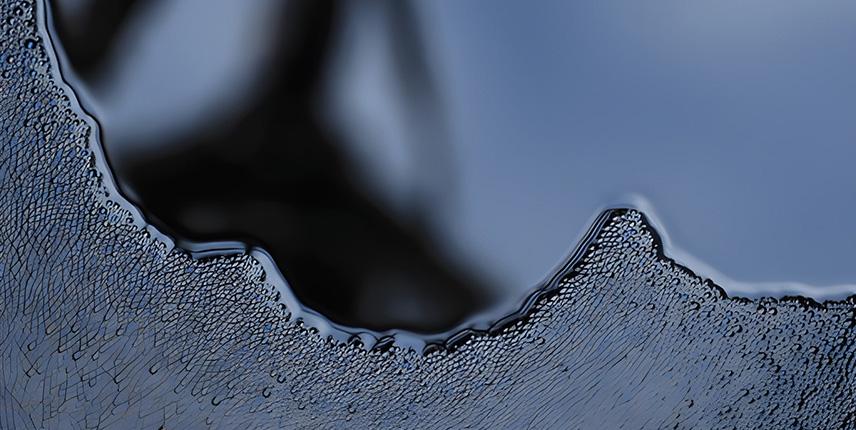

Bitumen, a key material in road construction and waterproofing, is derived from the refining of crude oil. Through a carefully controlled process, lighter hydrocarbons such as gasoline, diesel, and kerosene are removed, leaving behind the heavier residue known as bitumen.

The bitumen production process involves several stages, from crude oil distillation to further refining and modification, ensuring the final product meets the quality and performance standards required for diverse industrial applications.

Overview of Bitumen Production

Bitumen is not a naturally occurring byproduct of refining but a purposefully engineered material. Modern refineries are designed to extract and enhance it for use in asphalt paving, roofing, and waterproofing.

The production process mainly focuses on separating the heavier components of crude oil and then treating them to achieve desired physical and chemical properties.

Step 1 – Atmospheric Distillation

The first stage in producing bitumen is atmospheric distillation.

Crude oil is heated to around 350–400°C in a distillation column. As it vaporizes, the lighter hydrocarbons, including gasoline, kerosene, and diesel, rise to the top and are separated.

The heavier residue, which doesn’t vaporize at this stage, remains at the bottom of the column. This residue becomes the feedstock for the next stage: vacuum distillation.

Step 2 – Vacuum Distillation

In the vacuum distillation unit, the remaining heavy residue from atmospheric distillation is processed under reduced pressure. Lowering the pressure allows distillation to continue at a lower temperature, preventing thermal cracking of the material.

This step removes the remaining lighter fractions, resulting in a vacuum residue, a thick, viscous material that forms the base for straight-run bitumen (the most common type used in road construction).

Step 3 – Air Blowing and Oxidation (Optional)

In some cases, the bitumen is further processed through an air blowing or oxidation process. During this step, air is blown through the heated vacuum residue, causing chemical reactions that increase the bitumen’s softening point and viscosity.

This results in oxidized bitumen, which is more resistant to heat and aging, ideal for roofing materials, waterproof membranes, and industrial coatings.

Step 4 – Bitumen Modification

To meet modern performance standards, bitumen is often modified with polymers, rubber, or chemical additives.

This process produces Polymer-Modified Bitumen (PMB), which offers:

- Greater flexibility and durability

- Improved resistance to deformation under heat

- Enhanced adhesion and elasticity

Modified bitumen is especially used in high-traffic roads, extreme climates, and specialized waterproofing systems.

Quality Control and Testing

Before distribution, every batch of bitumen undergoes rigorous quality testing to ensure compliance with international standards (such as ASTM or EN).

Tests include:

- Penetration and softening point tests

- Viscosity and ductility measurements

- Adhesion and aging resistance checks

These ensure the final bitumen product performs reliably across construction, industrial, and environmental conditions.

Environmental Considerations

Modern refineries focus on reducing emissions and waste during bitumen production.

By optimizing the refining process and incorporating recycling technologies such as Reclaimed Asphalt Pavement (RAP), the industry minimizes environmental impact while maintaining efficiency and product quality.

Conclusion

The bitumen production process is a highly refined and controlled operation that transforms crude oil into one of the most vital materials for infrastructure and industry.

Through stages like atmospheric and vacuum distillation, followed by modification and testing, refineries ensure that every batch of bitumen meets strict durability and performance standards.

From roads and runways to roofs and pipelines, bitumen remains the backbone of modern construction, engineered for strength, reliability, and sustainability.