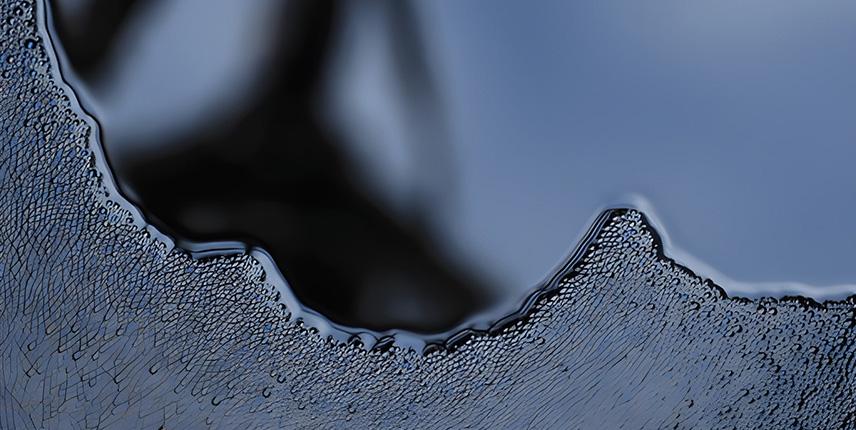

Bitumen Packing

Proper bitumen packing is a crucial part of ensuring product quality, safety, and efficiency during transportation and storage. Since bitumen is a highly viscous and temperature-sensitive material, it requires specialized packaging that maintains its consistency and prevents contamination or leakage.

At Bernet Bitumen, we provide a range of reliable and customizable bitumen packing solutions to meet the unique needs of our domestic and international clients. Whether for small-scale use or large industrial projects, our packaging is designed to ensure safe handling, efficient transport, and long-lasting quality.

Importance of Proper Bitumen Packing

Proper packing is not just about convenience, it directly impacts product integrity, logistics, and operational costs.

Well-designed bitumen packaging ensures:

- Leak-free transport and safe handling.

- Preservation of product quality by protecting against temperature fluctuations.

- Reduced waste and loss during filling, transport, and unloading.

- Optimized logistics, enabling easier loading and unloading.

- Compliance with export and safety standards for international shipments.

Selecting the right packing solution helps companies achieve cost-efficiency while maintaining top-quality bitumen ready for immediate application.

Types of Bitumen Packing Offered by Bernet Bitumen

We offer a wide range of bitumen packaging options, each tailored to specific project requirements, shipment sizes, and destination conditions.

1. Steel Drums

Steel drums are one of the most popular and secure methods for packing bitumen.

At Bernet Bitumen, we supply:

- 180 kg steel drums (standard export size)

- 150 kg steel drums (for smaller batches)

Advantages:

- Durable and strong for long-distance shipping.

- Suitable for both hot and cold climates.

- Stackable, easy to store, and recyclable.

Steel drums are ideal for export shipments and medium-sized projects that require easy handling and high protection standards.

2. Jumbo Bags

Jumbo bags, also known as big bags or bulk bags, are designed for bulk bitumen packaging.

They are lined with heat-resistant material and are suitable for solid or semi-solid bitumen.

Benefits:

- Lightweight and cost-effective.

- Easy to load and unload.

- Suitable for containerized transport and large-scale construction projects.

Jumbo bags help reduce packaging waste and optimize space for efficient international transport.

3. Poly Bags

Poly bags are an innovative solution for solid bitumen packing. They are made of meltable plastic material, allowing the bag to melt during heating, eliminating the need for manual unpacking.

Advantages:

- No residue or waste after melting.

- Easy handling and storage.

- Perfect for small and medium-sized projects or remote job sites.

This eco-friendly method is gaining popularity due to its convenience and efficiency.

4. Carton Boxes

Carton box packing is another efficient and sustainable method for solid bitumen. Each box typically contains a defined weight (e.g., 20–25 kg) for easy manual handling.

Key Features:

- Compact and user-friendly.

- Suitable for retail or smaller industrial needs.

- Ensures safe, clean, and easy-to-store bitumen packaging.

Carton boxes are ideal for domestic transport and projects requiring precise quantities.

5. Flexitanks

Flexitanks are large, flexible containers used for bulk bitumen transport in liquid form. They are installed inside standard 20-foot shipping containers and can hold up to 24 metric tons of product.

Advantages:

- Excellent for long-distance export shipping.

- Cost-effective compared to steel drums.

- Reduces packaging waste and handling time.

Flexitanks are the preferred choice for high-volume international deliveries of hot bitumen.

6. Bitutainers

Bitutainers are specially designed tank containers for storing and transporting hot bitumen in bulk. These reusable containers are insulated and equipped with heating systems to maintain optimal temperature during transit.

Key Benefits:

- Suitable for large infrastructure projects.

- Ensures consistent product temperature and quality.

- Environmentally friendly and reusable.

Bitutainers are ideal for overseas shipments and bulk road construction contracts requiring efficient, large-scale supply chains.

7. Bulk Bitumen (Hot Bulk Delivery)

For major projects or domestic deliveries, bulk bitumen is supplied directly via heated tankers or bulk vessels.

This method is ideal for:

- High-volume infrastructure projects.

- Asphalt mixing plants.

- Industrial-scale waterproofing applications.

It minimizes handling time and cost while ensuring fresh, high-quality bitumen upon delivery.

Choosing the Right Bitumen Packing Solution

When selecting the appropriate bitumen packaging method, it’s essential to consider:

- Project size and scale (small, medium, or large).

- Transportation mode (road, sea, or rail).

- Destination climate and distance.

- Storage and heating facilities at the site.

At Bernet Bitumen, our experts help clients choose the most efficient and cost-effective packing solution to match their exact project needs, ensuring safe delivery, reduced waste, and long-term satisfaction.

Conclusion

Effective bitumen packing ensures that the material arrives at its destination in perfect condition, ready for use. Whether shipped in steel drums, jumbo bags, poly bags, flexitanks, or bitutainers, proper packaging helps maintain quality, minimize loss, and streamline logistics.

By selecting the right packing solution, construction companies can achieve greater efficiency, lower costs, and guaranteed product reliability, all crucial factors in delivering successful projects.